QiOVA has successfully designed and developed the programmable multi beam technology shaping OEM systems, thus boosting the efficacy and profitability of laser material processing. QiOVA is a French company founded in 2011 with a specialization in the fields of laser and photonics. QiOVA is a trailblazer in the development of programmable laser beam shaping for high power and high energy applications. QiOVA ‘s head office is located in Saint-Etienne, in the region of Lyon, a prominent centre of French Technology.

QiOVA has successfully designed and developed the programmable multi beam technology shaping OEM systems, thus boosting the efficacy and profitability of laser material processing. QiOVA is a French company founded in 2011 with a specialization in the fields of laser and photonics. QiOVA is a trailblazer in the development of programmable laser beam shaping for high power and high energy applications. QiOVA ‘s head office is located in Saint-Etienne, in the region of Lyon, a prominent centre of French Technology.

C. And C. Laser Engineering offers products from QiOVA Lasers in India.

Laser technology is here to stay as a premier technology that will produce quality output in a huge quantity with maximum precision. Moreover, laser procedures will be non-contact, flexible and will create the least impact on the environment. Laser technology generally is limited to a scanner with a single laser beam moving over the target and producing the output.

QiOVA has created a revolution in laser technology by developing and patenting multi-beam technology. This multi-beam technology is QiOVA’s patented technology and the procedure involves the simultaneous use of hundred beams with micrometric precision and ultra-high throughput.

Products from QiOVA

VULQ1 Product Line

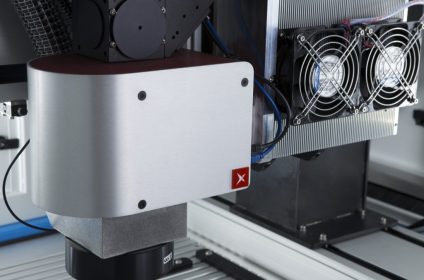

QiOVA industrial programmable laser beam shaping platform named VULQ1 is patented and based on multibeam technology. VULQ1 is a programmable laser beam shaping OEM system that has been designed to perform applications across a varied range of industrial sectors. VULQ1 technology has a unique and distinctive feature of combining ultra-high-speed processing capabilities with operational flexibility.

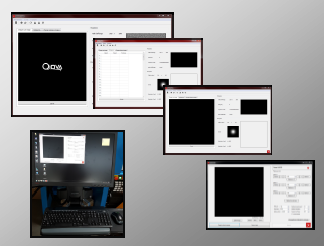

Live demonstration of dynamic laser beam shaping with VULQ1

Salient features and applications of VULQ1

- When applied to micromachining, VULQ1 increases the process productivity and process parallelization significantly.

- The flexibility offered by the laser tools enables the creation and market of the product in a short period of time and thus providing a speedy return on investment.

- Applications such as Surface texturing with the utmost precision in aeronautics and solar industries and drilling micro-holes at a fast pace offering considerable benefits in pharmaceutical or biomedical devices.

- VULQ1 offers optimum returns in laser material processing with a negligible change in the existing tool design settings.

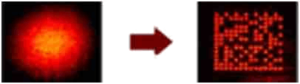

- VULQ1 generates a set of 10,100 or 1000 of beamlets from one single Gaussian laser beam with the energy and location of the beamlets is monitored independently by the software.

- VULQ1 integration is hassle-free

- VULQ1 is designed so that it can be mounted like a scanner.

- VULQ1 operating is smooth – the software Beam-forge from QiOVA combines beam shaping performance with a customer-friendly and ergonomic interface

- VULQ1 delivers excellent throughput and hence offers options to choose, for optimization of the process.

Applications of QiOVA Lasers

Stamp Marking

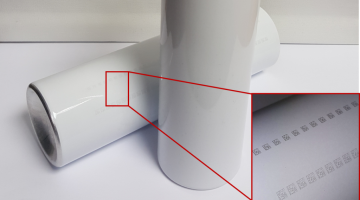

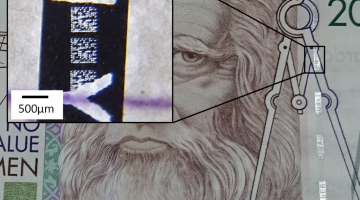

QiOVA’s Stamp marking proficiency is useful in marking 2D patterns such as 2D barcodes and even pictures and characters with one single laser pulse.

Stamp marking offers a massive production boost for 2D barcode marking with a seamless procedure from QiOVA. The QiOVA’s stamp marking competency is such that even in marking-in-line and with the pattern size down to 100 microns, the resulting output has spotless readability without any type of distortion, as all the dots are marked simultaneously.

Micromachining

Benefits of VULQ1 from QiOVA for Micromachining

Ultra-high-speed Processing and Increase in Productivity

- Voluminous increase of process speed with parallelization

- Quality is not compromised even though Speed increases thus boosting productivity

- Maximum usage of the laser capital equipment with parallelization

- Enhances return on investment

Adaptability

- The laser tool can be changed using software

- Many different combinations can be tried out on the same machine to develop various different product modules